Related Solutions

Quick Links

|

|

Key Features

Applications:

|

Chroma 17010 Battery Reliability Test System is a high-precision system designed specifically for testing lithium-ion battery (LIB) cells, electric double-layer capacitors (EDLCs), and lithium-ion capacitors (LICs). The test equipment is suitable for product development and quality control by providing characteristic research, cycle life testing, product screening, and quality assessment. Chroma 17010 with exclusive Battery Lab Expert (Battery LEx) software platform, helping users to quickly reference previous sub-recipes or add new sub-recipes through a multi-level recipe structure for efficient test plan editing. The independent DUT data management function can share different DUT recipes.

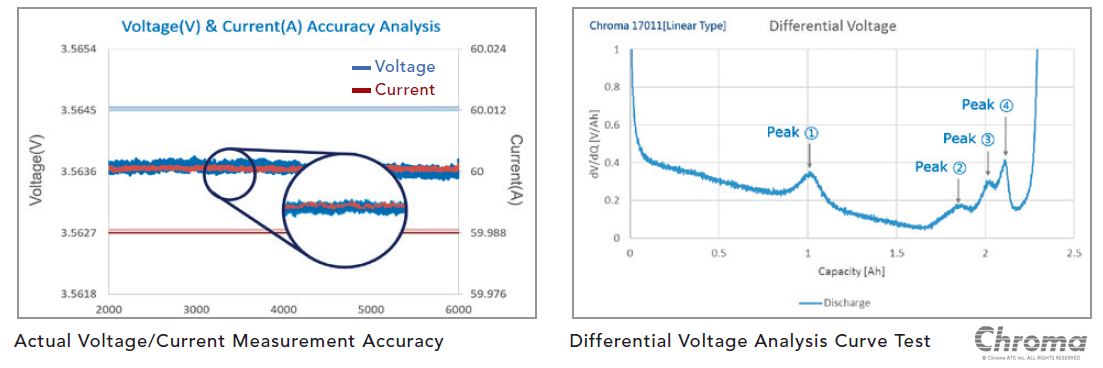

Stable & Low Noise Output

Chroma 17010 is equipped with low output noise and high measurement accuracy. The test current and voltage data can be converted into highly accurate and clear characteristic peaks to efficiently research the aging mechanism of Li-ion batteries.

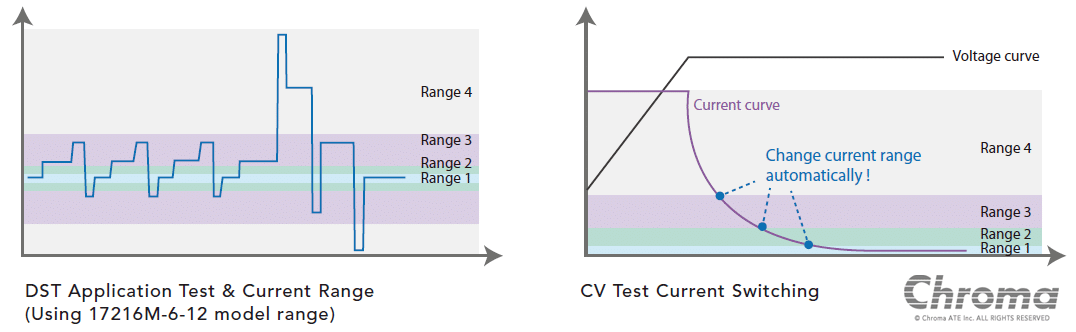

High-Precision & Multiple Current Range Design

- Quick switching of current ranges: Chroma 17010 series provide multiple current outputs and measurement range switching, fitting test plans with both large and small currents. At the start of a test step, the system will detect the output current and then automatically and quickly switch to the appropriate current range. This improves the test accuracy and resolution for highly accurate test data.

- Automatic range switching under constant voltage mode: Chroma 17010 linear circuit models support automatic switching of the current range in the constant voltage test mode, without any output interruption. This is perfect for applications such as float charging or potential regulation, which require long-term and highly stable testing of extremely small current output.

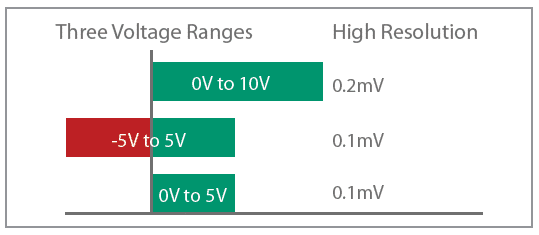

Three Voltage Ranges

- 0V – +5V: Half-cell, full-cell, EDLC testing

- 0V – +10V: Batteries in series, EDLC testing

- -5V – +5V: Symmetric battery testing

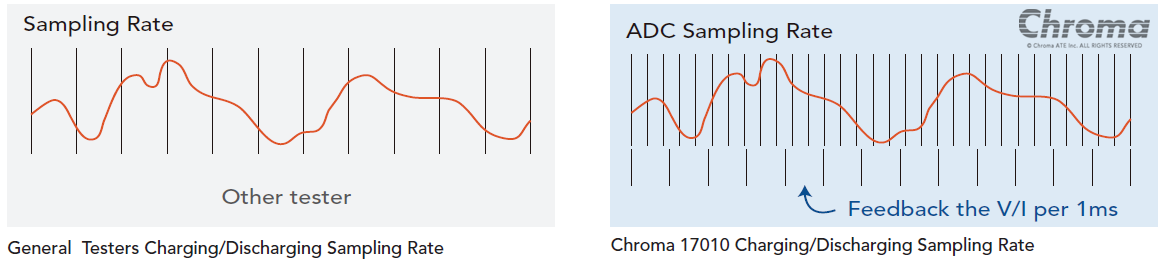

High Speed Sampling Technology

Chroma 17010 uses high-speed voltage and current sampling with double integration of computing to capture transient changes in the test without distortion. The advanced test system provides more accurate capacity calculations to solve the issue that general battery test equipment only use the report sampling speed to record key data, causing large cumulative errors.

- Hardware internal voltage/current sampling rate: 1mS

- Report single point transient sampling rate: 1mS

- Report sampling rate: 10mS

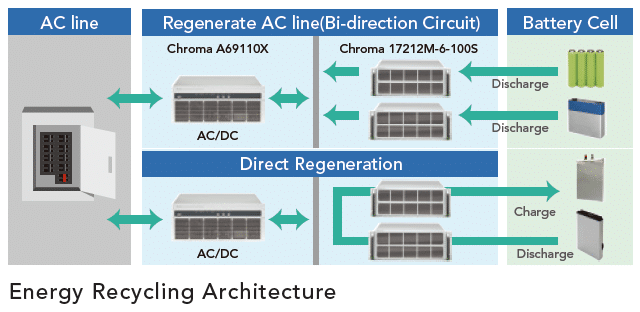

Energy Recycling

Chroma 17010 large current models have a high-precision, high-efficiency and power-optimized energy recycling architecture that achieve green and low-carbon performance. The test system so avoids electricity waste heat due to load consumption during discharge.

- DC: Automatically prioritize discharged energy to charging channels with >80% recycling efficiency.

- AC: Recover excess energy to the AC line, with >60% recycling efficiency.

- Feed back current to the grid with <5% total harmonic distortion.

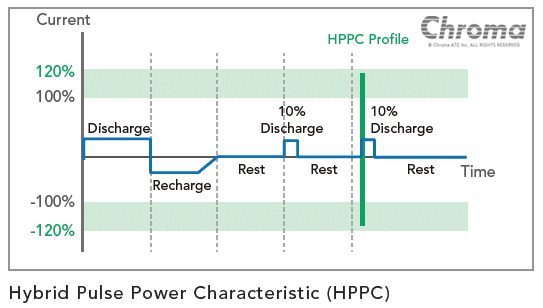

Super Charge/Discharge Output Mode

Chroma 17010 regenerative models provide up to 30 sec. super output functionality. For short-time & high-current pulse applications, the super mode can be set and executed directly through steps, and provides an even wider range of current and power usage.

- 17212M-6-100: CC and CP 120% charge/discharge output

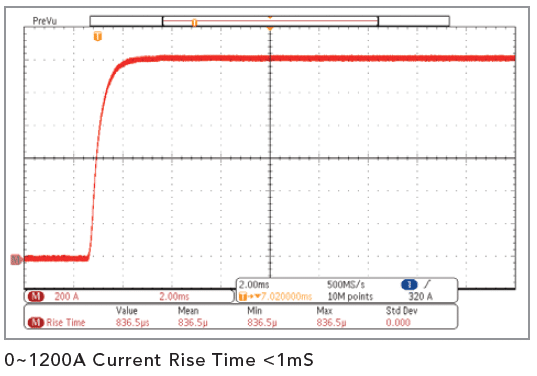

Fast Current Response (<1mS)

Chroma 17010 regenerative models are provided with current response time of 0-1200A in less than 1mS, which can more realistically simulate the instantaneous peak current of battery charging and discharging behavior when driving, and also meets NEDC, FUDS, and DST test standards.

- 17212M-6-100S:10% to 90% < 1mS

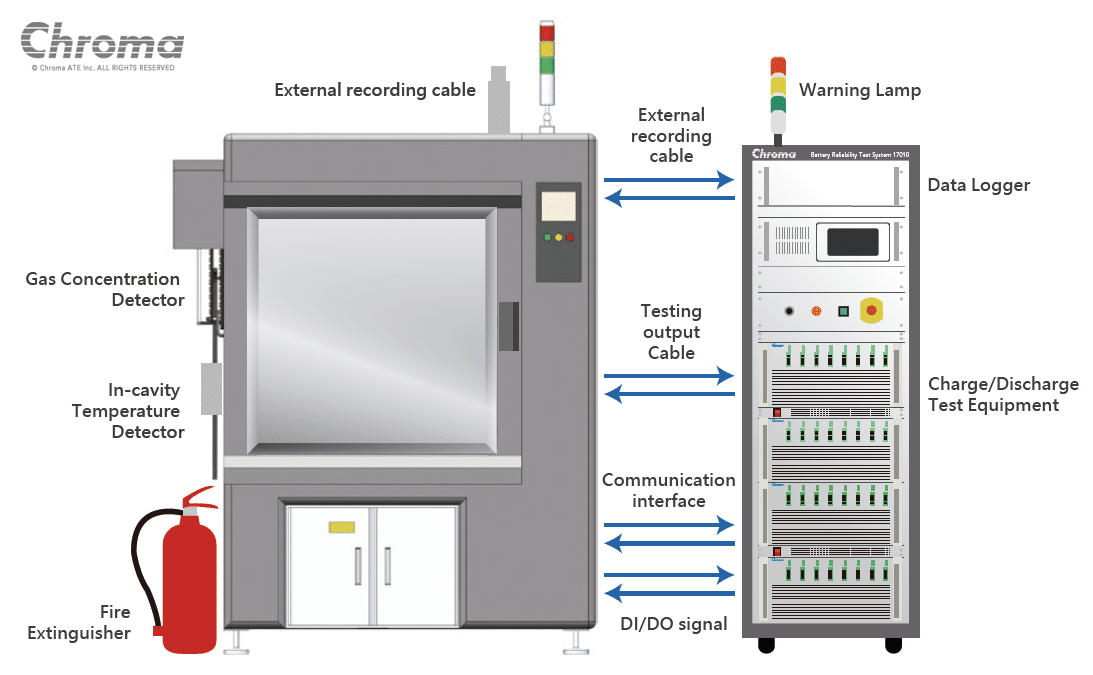

Chroma 17010 supports integration of a variety of renowned environmental chambers and multi-functional data loggers. The Battery LEx software can simultaneously set parameters and monitor data, as well as automatically merge test data into the test report, thus providing users with the most complete test solution.

1. Integrable data logger

- Recording temperature (°C), voltage (V), pressure (mPa), force (kg).

- External real-time data can serve as cut-off or protection judgments (temperature).

2. System protection and abnormality detection

- Following the numerous built-in recipe protections, the protection mechanism monitors and triggers with a response speed of 1mS. An independent external voltage/temperature meter relay is optional to achieve reliable two-level protection.

- Real-time abnormality detection in each tester automatically detects deviations based on independent logic. When the system is interrupted, the test can be continued after the exception is eliminated without missing any data.

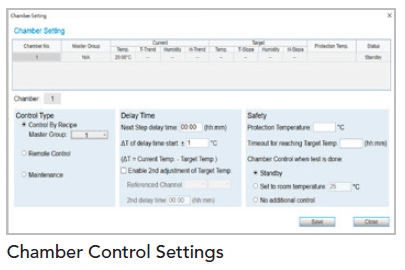

3. Integrable chamber and peripheral safety device

- The Battery LEx software provides built-in chamber setting controller and chamber control steps, which can control temperature and humidity, indicate the temperature control time, delay time, and standby temperature, as well as control timeout and over-temperature protections.

- To ensure consistency of the test state, the grouping management structure allows all testing channels in the same chamber to enter the temperature control phase at the same time.

- The built-in DI/DO function can be connected with smoke/gas detection, fire extinguisher, and alarms for over-temperature, over-voltage, and open door. The system performs different levels of handling according to the degree of damage, including stopping

- the test or powering off. Alarm data can be sent remotely via e-mail.

Battery Lab Expert (Battery LEx) is the testing software platform specially developed for Chroma 17010 and offers:

- Group testing: Each group can control up to 96 channels and execute up to 50,000 steps.

- Variable editing: Using the data from the external data logger for flexible programming and complex applications.

- Chamber integration: DI/DO amplification monitors the chamber’s status and protection mechanisms in real time.

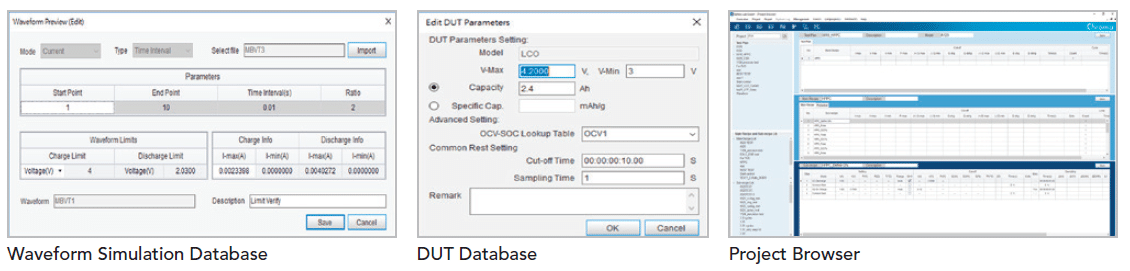

Project Browser

- Create up to 500 projects and construct corresponding test plans according to different DUT types or requirements.

- Quickly insert corresponding parameters from DUT database when editing recipe, and easily share recipes to different DUTs.

- Waveform simulation folder: Import .xlsx data points to the folder, the waveform simulation can set the time interval

- fixed/user defined), output magnification, and data range.

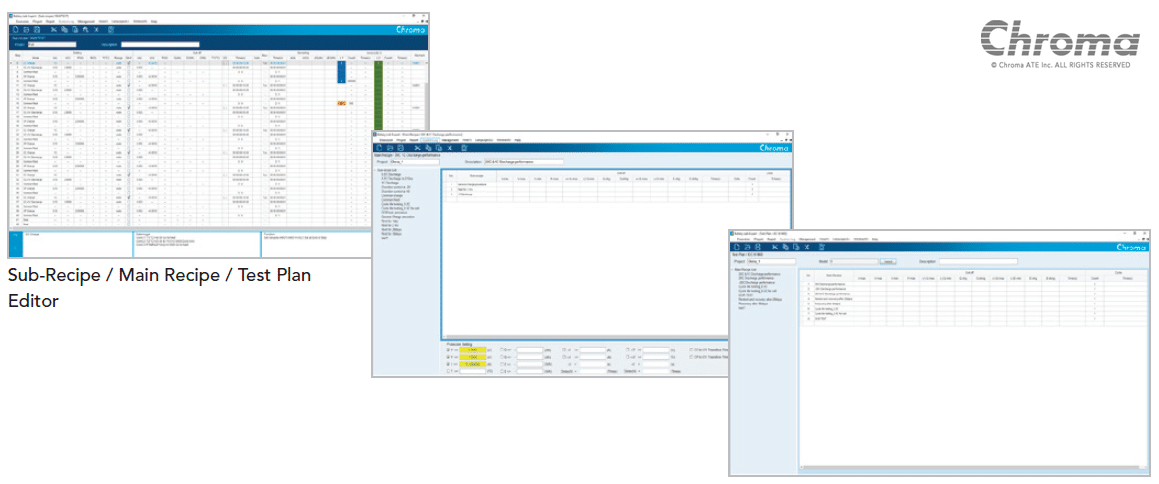

Recipe Editor

In the hierarchical editing structure (test plan → main recipe → sub-recipe), users can directly share existing recipes by replacing the DUT specifications or quickly complete a plan by flexibly combining existing sub-recipes.

- Step types: CC / CV / CP / CC-CP / CC-CV / CR / Waveform / Rest / Common Rest / Chamber Control / Super CC / Super CP

- Cut-off conditions: Step cut-off / Recipe cut-off / External parameter cut-off

- Go to: Next, End, Jump, If-then logic jump.

- Special input methods: C-rate, OCV-SOC, Q%, ±V, Variable.

- Four-level Cycles: Single cycle up to 999,999 times.

- 1mS~100mS transient capture of the variable at the start of the step, or records the test value at the start/end of the step and defines it as a variable for secondary calculation.

- Recipe protections: Voltage, Current, Chamber Temperature, Energy, Capacity, Current/Voltage Change, CC-CV/CP-CV Transition Time.

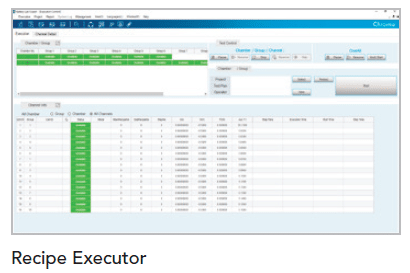

Recipe Executor

The recipe executor adopts group management according to different test plans. All channels in the group will simultaneously start testing and display their real-time test status. When integrated with a chamber, each channel will automatically perform a waiting mechanism, and the temperature control will not start until all the channels reach the same condition. When there are multiple groups in the chamber, they can be set to wait between groups.

- 17212M-6-100S:10% to 90% < 1mS

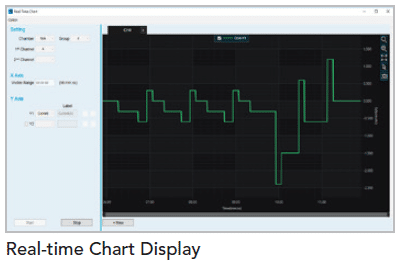

Real-time Chart Display

Display charging and discharging curves in real time while testing. Users can zoom in and out on data and display data values by dragging the mouse, as well as flexibly select any channel and axis item.

- Real-time charting based on the user-defined sampling time of up to 36,000 data points per screen.

- Up to 4 sets of real-time display screens, with test comparison for up to 2 channels per screen.

- Time freeze function to store test curves.

- Dual y-axis data display.

Test Report

- Export modes: auto export of sub-recipe, manual export of test plan.

- The system can adjust effective digits in the data up to 9 decimal places.

- Report types: channel report, step report.

Chamber Control and System DI/DO Signal Control

- Triple chamber control: chamber control step, real-time remote control, and maintenance mode.

- Delay time: set the rest time after reaching the set temperature to secure similar temperatures between the DUT and chamber.

- Double temperature adjustment: the temperature logger adjusts the chamber to ensure that the chamber and DUT’s actual temperature are the exact same.

- Chamber actions after testing: maintain, end, or adjust the temperature control.

- Dual chamber protection control: over-temperature and overtime.

- Tri-color warning light signal and relay signal are provided.

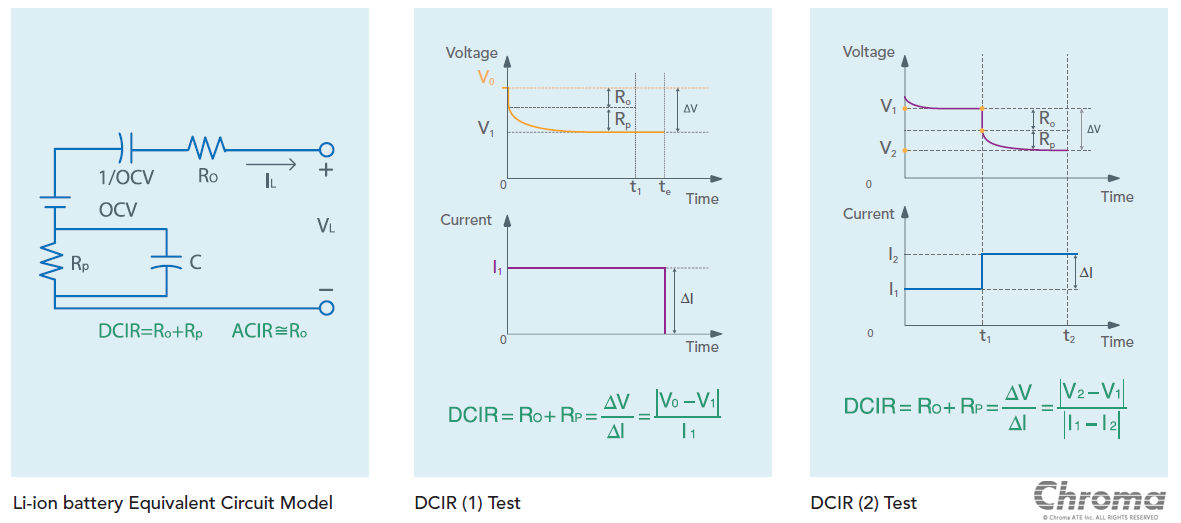

Direct Current Internal Resistance (DCIR)

The battery’s internal resistance value is related to its charge/discharge ratio. The larger the internal resistance value, the lower the efficiency when temperature rises. ACIR measurement of traditional 1KHz LCR meters can only evaluate the ohmic resistance (Ro) of the battery that affects the instantaneous power output, but is unable to evaluate the polarization resistance (Rp) produced during electrochemical reaction. DCIR assessment includes ACIR and comes closer to the actual polarization effect of the battery under continuous power application. Chroma 17010 has two programmable DCIR test modes, and – with the variable calculation function – can automatically obtain test results that meet the IEC 61960 standard.

- DCIR (1) is based on the voltage difference caused by one current change.

- DCIR (2) is based on the voltage difference caused by the change between two currents.

|

|

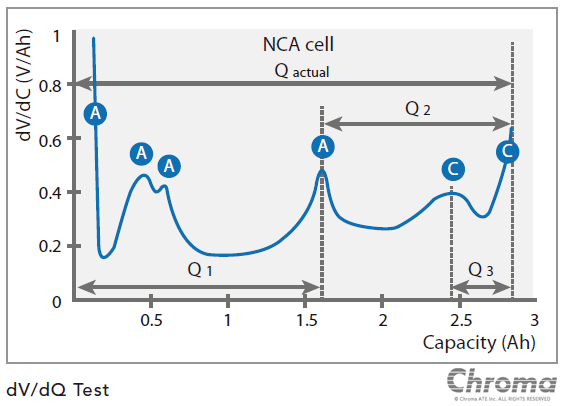

Differential Voltage (dV/dQ)The key to plotting the dV/dQ curve is to charge and discharge the battery with a small current ( < C/20) in order to eliminate polarization effects on the test results. Chroma 17010 has low noise to draw high-definition dV/dQ vs. Q curves, users can view and mark each characteristic peak in detail. The ageing test allows users to analyze the battery’s aging system based on the deviation and height of each characteristic peak. |

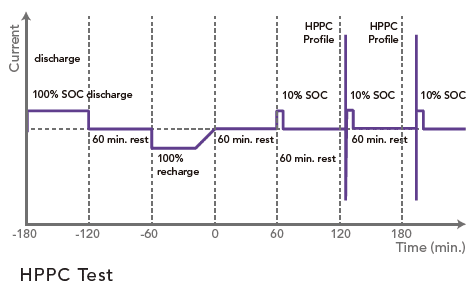

Hybrid Pulse Power Characteristic (HPPC)Chroma 17010 has a flexible editing program that can compile HPPC test steps, as used by the U.S. Council for Automotive Research (USCAR) to evaluate the battery performance of new energy vehicles. The purpose is to obtain the open circuit voltage, ohmic resistance (Ro), and polarization resistance (Rp) data of a specific depth of discharge within the operating voltage range, following standard test methods. It establishes a functional relationship between the depth of discharge and the charge/discharge peak power, as an index to evaluate the battery cell’s aging and output power capacity. |

|

|

Battery CapacityThe capacity can be obtained by integrating current over time, from the start of charging/discharging until the cut-off condition is reached. Common test items include current ratio and temperature characteristics. Comparing the results lets users analyze performance differences between products. Higher accuracy of current/voltage measurement and faster sampling enable to distinguish more accurately the differences in battery cell capacity. |

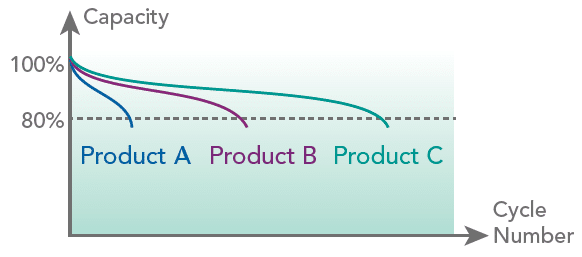

Battery Cycle LifeCycle life is one of the most important test items for batteries. In accordance with the experimental purpose, it tests the same battery through repeated charge and discharge conditions until the capacity falls to 80%, and then calculates the number of cycles. The cycle life test can be used to evaluate battery performance or define proper conditions of use. |

|

|

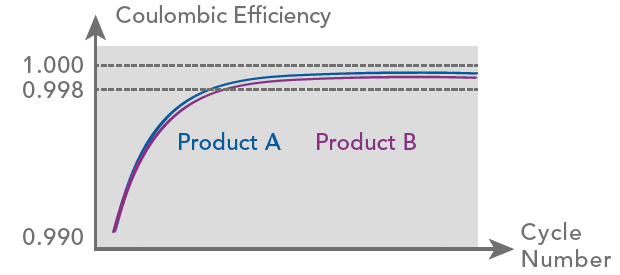

Coulombic Efficiency (CE)CE is calculated by the charge/discharge capacity ratio when the battery is fully charged and then fully discharged. Good batteries have higher CE, and need high precision and stable equipment to distinguish differences. Chroma 17010 offers accurate CE testing that can estimate the battery lifespan with only a few cycles. |

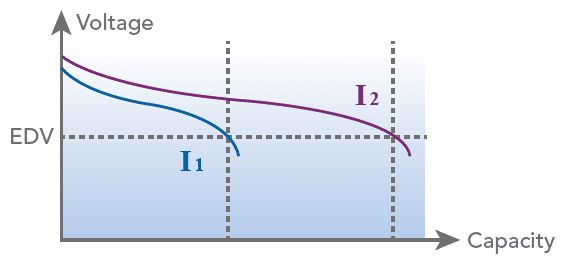

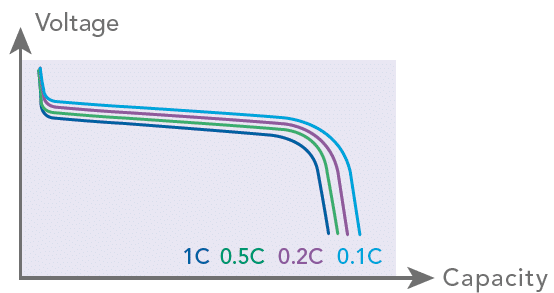

Charge & Discharge RateThe battery is charged and discharged at different currents to evaluate how its voltage platform and capacitance maintain. Such test results are often used for adjusting the proportion of active materials during product development as well as for verifying performance of power batteries for rapid charging and discharging. |

Battery Cell Test System Auto Calibrator

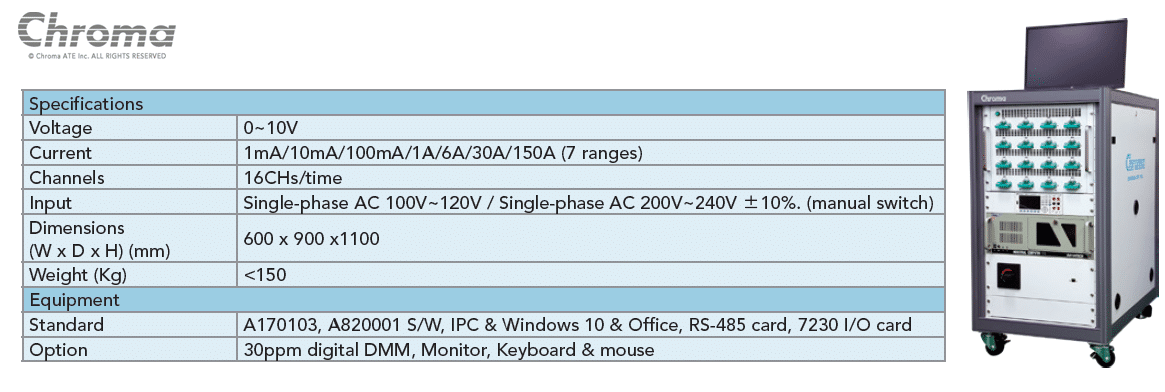

Chroma A170103 is a complete automated calibration and verification equipment with a variety of high-precision calibration standard components built-in for programmable test tasks. Chroma A170103 applies to Chroma 17010 products up to 150A in order to ensure that the equipment maintains its high precision and traceability.

- Consistent standards verification: reducing human errors and test variables.

- Efficient calibration and verification: cutting down labor costs.

- Automated report generation: managing maintenance records and traceability.

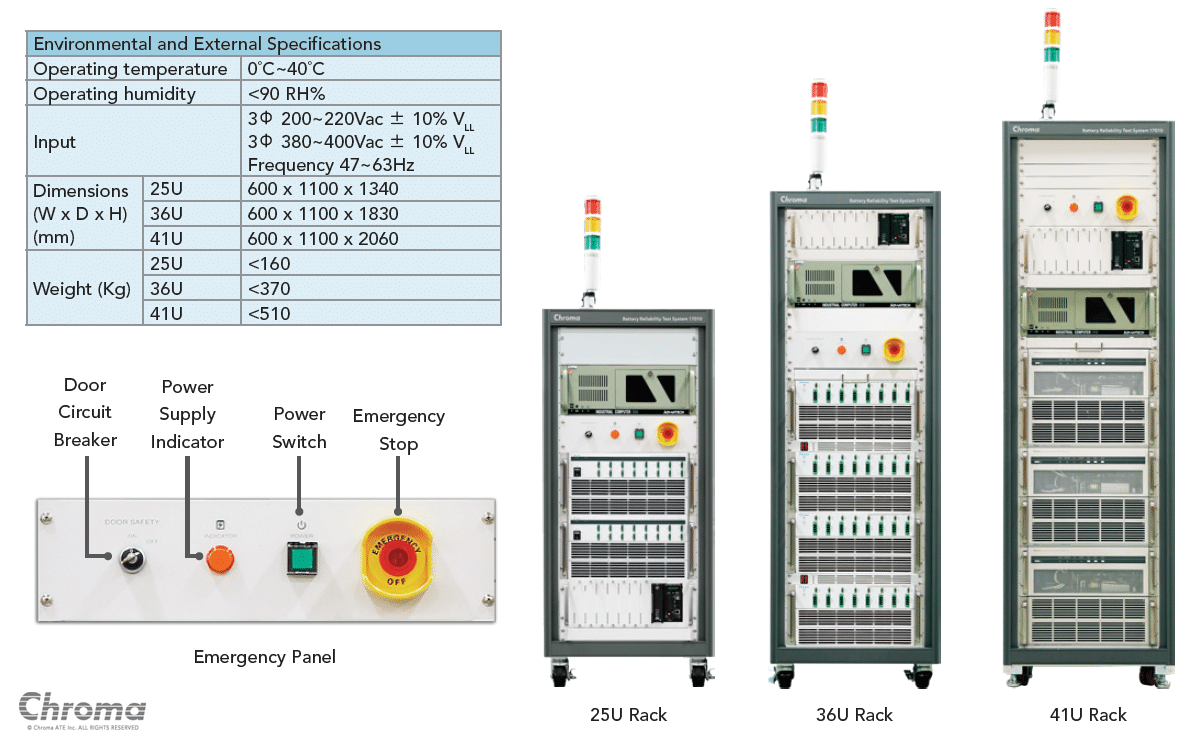

Environmental & External Specifications

Home | Solutions | Support | Press Center | About Chroma | Contact

Copyright © Chroma ATE, Inc. All Rights Reserved.